Improving Protective Covers

July 8, 2014Elementary, my dear Watson The victim is sprawled out on the floor, cold-dead with a gaping gash across the bellows. The usual suspects have been brought in: Corrosion, the fatigue twins – Vibration and Flow, Squirm, and Installation Damage. “The killer is indeed in this very room!” I pronounce, wishing I had a pipe to

Read More

Bellows Damage Counseling

August 31, 2016Damaged relationships Several years ago my wife put a dent in the side of my truck while negotiating a tight turn in a school parking lot. I have not had that dent fixed. I could give lots of reasons for not fixing it: it doesn’t affect the function of my truck, too costly to repair,

Read More

Water Hammer In Piping

June 29, 2016

The Heartache of Thermal Shock

April 18, 2016Why your stainless steel ducting system is breaking up with you Hot tempered My wife warped an empty stainless steel cooking pan by starting the burner on high; this even after my repeated lessons to her on principles of thermal shock. My engineering educational efforts are always met with eyerolls and the occasional rude raspberry.

Read More

Understanding Bellows Pressure Capacity

July 11, 2014

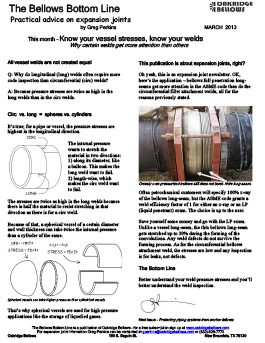

NDE On Welds

July 9, 2014All vessel welds are not created equalQ: Why do longitudinal (long) welds often require more code inspection than circumferential (circ) welds? A: Because pressure stresses are twice as high in the long welds than in the circ welds. Circ vs. long = spheres vs. cylinders It’s true; for a pipe or vessel, the pressure stresses

Read More

Cryogenic Properties of Stainless Steel Bellows

July 9, 2014The Cold Facts Most everybody in the free world knows that stainless steel is a good material for high temperatures. It is also commonly used in very cold applications. Stainless steel not only has good properties at cryogenic temperatures – it is actually a BETTER material than it is at room temperature. The Cold War

Read More

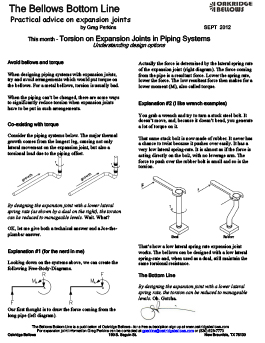

Torsion on Expansion Joints in Piping Systems

July 12, 2014Torsion on Expansion Joints in Piping Systems Understanding design Avoid bellows and torque When designing piping systems with expansion joints, try and avoid arrangements which would put torque on the bellows. For a metal bellows, torsion is usually bad. When the piping can’t be changed, there are some ways to significantly reduce torsion when expansion

Read More

Why Stainless Steel Doesn’t Rust

July 12, 2014A tale of two metals Most bellows are made from 300 series stainless steel and so that ‘wonder’ metal is worth discussing. You take the standard mixture for steel – iron and carbon, and add a little chromium and nickel, and POW! You get a steel that doesn’t rust. Both metals have a high percentage

Read More

Moving Laterally in an Axial World

July 12, 2014Going in another direction Henry David Thoreau once wrote, “If a man does not keep pace with his companion, perhaps it is because he hears a different drummer,” to which his father promptly responded “Hey, drummer boy! Get your beatnik friends out of my house and go get a job!” Many types of expansion joints

Read More

Forced Outage Emergency Recovery Tip

January 13, 2018There is no excerpt because this is a protected post.

Read More

GE Condenser Emergency Repair

January 13, 2018There is no excerpt because this is a protected post.

Read More

Forced Outage Emergency Recovery Tip

July 19, 2017There is no excerpt because this is a protected post.

Read More

GE Condenser Emergency Repair

November 30, 2016There is no excerpt because this is a protected post.

Read More

Part 1 – Thermal Growth

June 2, 2016

Part 4 – Tied Universal Expansion Joints

March 7, 2020Length: 1.00 (Click image to launch video)

Read More

Part 4 – Tied Universal Expansion Joints

February 12, 2020

Part 5 – Expansion Joint Field Inspection

March 7, 2020Length: 1.00 (Click image to launch video)

Read More

Part 5 – Expansion Joint Field Inspection

February 12, 2020

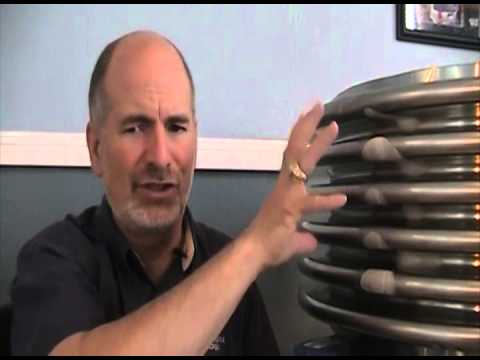

How A Metal Bellows Is Made

August 15, 2023This video shows you how a metal bellows is made. This is a video that is of interest to design and maintenance engineers. Length: 0.37

Read More

Round Corner Metal Rectangular Expansion Joint (New)

December 18, 2014Metal rectangular expansion joints with round corners and U-profiles significantly out-perform any other corner style, as demonstrated by this video. The more flexible a bellows, the higher its fatigue life. This video is of interest to design and maintenance engineers. This is a video that is of interest to design and maintenance engineers. Length: 0.57

Read More

Camera Corner Bellows

September 5, 2014Camera corner metal rectangular expansion joints have proven to be problematic for end users. The design requires considerable amounts of welding in the corners which are a stress riser during deflection. In addition the tight pitch of the profile more easily traps debris. This is a video that is of interest to design, piping, vessel

Read More

Inspecting Metal Bellows Damage

August 1, 2014A metal bellows can be easily damaged if installers are not careful. The dents, arc strikes, and scratches are not always a cause for immediate panic. This is a video that is of interest to maintenance engineers, inspectors, pipefitters, and contractors. Length: 3:37

Read More

Lugs on Pipe and Vessels *NEW*

November 30, 2015Load bearing lugs generate local bending stresses on thin walled shells such as pipe or vessels; these stresses can easily be reduced by optimizing the material arrangement. There are several methods for calculating the shell stresses which are covered in publications on the theory of plates and shells. This short video introduces visual concepts on

Read More

(Weld) Sugar – Why It’s Bad For You

June 11, 2020

Acid condensate on metal bellows expansion joint

May 26, 2014High temperature flue gas ducting often has metal bellows expansion joints that are internally insulation. Make sure the bellows remains above 400F to prevent acids from condensating and causing corrosion failures This is a video that is of interest to design and maintenance engineers. Length: 1.33 (Click image to launch video)

Read More

Edge Welded Bellows *NEW*

September 5, 2014Edge welded metal bellows provide large movements with very low spring rates in round or rectangular ducting systems. This style is can be designed in short over all lengths. This is a video that is of interest to design and maintenance engineers. Length: 0.57 (Click image to launch video)

Read More

Metal Rectangular Expansion Joints

August 1, 2014Are all metal rectangular expansion joints created equal? Not even close. Many after-market metal rectangles are made with a V-profile with a miter weld at the corners – these are flawed design features. The longest lasting designs have a U-profile with round corners. This is a video that is of interest to design and maintenance

Read More

Expansion Joint Liners

August 1, 2014

Van Stone Flanges

August 1, 2014

Why An Expansion Joint Works – Part I

July 11, 2014On the surface it doesn’t seem to make sense. If the code requires a pipe in a system to have a 3/8” thick wall to contain the internal pressure, how can an expansion joint bellows get by with just a 1/16” thick wall? Balance the Forces It’s how the material is arranged. For a pipe,

Read More

Why An Expansion Joint Works – Part II

July 12, 2014The bellows exposed There’s no mystery as to why a bellows can flex – it’s convoluted for crying out loud. This could be one short article. Except here’s the tantalizing part; when the bellows material flexes, the stresses shoot well into the plastic range. At this point the collective mechanical engineering community gasps, women faint,

Read More

EJMA verses ASME

August 1, 2014The EJMA design guide and the ASME code have different design criteria for metal bellows cycle life. The history of the ASME B31.3, Section VIII, and EJMA fatigue curves are discussed along with practical recommendations for expansion joint cycle life specifications. This is a video that is of interest to design, piping, and vessel engineers.

Read More

Fact or Myth? Metal Absorbs Water

July 28, 2020

When Weld Repairs Work – And We Don’t Know Why

February 26, 2020

Piping System Reliability

November 3, 2015Piping factoid Pumps, turbines, and other equipment connections last longer when expansion joints are designed into hot piping and ducting systems. Remembering what they do Think of a metal bellows as if it was a fuse in an electrical system – the bellows takes all the thermal growth movement so that the piping system and

Read More

Thermal Growth of Rings and Cylinders

May 8, 2015Expanding or contracting hole? Thermal growth Pop quiz! Oh stop complaining and get out a number 2 pencil. Show your work. As the metal disk in figure 1 gets hotter, the hole in the center will – a) Get smaller b) Get larger c) Stay the same Fig. 1 – From the book , Thinking

Read More

Party Conversations about Steam

February 19, 2015Steam completes us I have two books on my shelf about steam. Think about that; not one, but two. I have never read either of these books. It takes special people to write books about steam. Never, ever, Under.Any.Circumstance, sit next to such people at a party. Most of us make our living around equipment

Read More

More metal bellows repair tips

December 18, 2014This month – Protecting Piping From Anchor Failures – UPDATE Exciting new product – TIG wire with flux With the use of flux-core TIG wire, bellows weld repairs can now be made without the need for purging on the backside. The flux migrates to the backside of the weld shielding it from any oxygen. This

Read More

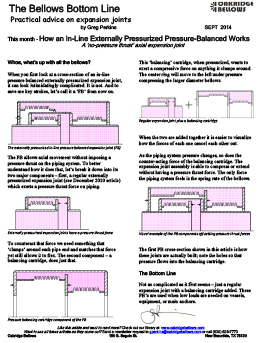

How an In-Line Externally Pressurized Pressure-Balanced Works

December 18, 2014Whoa, what’s up with all the bellows? When you first look at a cross-section of an in-line pressure balanced externally pressurized expansion joint, it can look intimidatingly complicated. It is not. And to save me key strokes, let’s call it a ‘PB’ from now on. The externally pressurized in‐line pressure balanced expansion joint (PB) The

Read More

Power Plant How a steam turbine cross over expansion joint works

January 13, 2018There is no excerpt because this is a protected post.

Read More

Power Plant Boiler Duct EJ Replacement

March 4, 2020There is no excerpt because this is a protected post.

Read More

Power Plant HRSG-Pen Seals

January 13, 2018There is no excerpt because this is a protected post.

Read More

Power Plant How a steam turbine cross over expansion joint works

September 4, 2015There is no excerpt because this is a protected post.

Read More

Power Plant Steam Extraction Expansion Joints

October 31, 2014There is no excerpt because this is a protected post.

Read More

Power Plant Coal Pulverizer Ducting Expansion Joints

January 13, 2018There is no excerpt because this is a protected post.

Read More

Power Plant Steam Turbine Cross Over Expansion Joint

October 31, 2014There is no excerpt because this is a protected post.

Read More

Power Plant 2-Ply Testable Bellows For Steam Turbines

January 13, 2018There is no excerpt because this is a protected post.

Read More

Power Plant 2-Ply Testable Bellows For Steam Turbines

October 31, 2014There is no excerpt because this is a protected post.

Read MorePower Plant GE Cross Over Steam Turbine Expansion Joint

January 13, 2018There is no excerpt because this is a protected post.

Read MorePower Plant GE Cross Over Steam Turbine Expansion Joint

October 31, 2014There is no excerpt because this is a protected post.

Read More

AEP-Box Fold Expansion Joints

January 13, 2018There is no excerpt because this is a protected post.

Read More

AEP-Box Fold Expansion Joints

October 27, 2014There is no excerpt because this is a protected post.

Read More

Avoiding Design Problems in Steam Extraction Expansion Joints

January 13, 2018There is no excerpt because this is a protected post.

Read More

Avoiding design problems in Steam Extraction Expansion Joints

October 27, 2014There is no excerpt because this is a protected post.

Read More

Case Study – Westinghouse Refurbishments

January 13, 2018There is no excerpt because this is a protected post.

Read More

Case Study – Westinghouse Refurbishments

October 27, 2014There is no excerpt because this is a protected post.

Read More

Case Study – Coal Pulverizer

January 13, 2018There is no excerpt because this is a protected post.

Read More

Case Study – Coal Pulverizer

October 27, 2014There is no excerpt because this is a protected post.

Read More

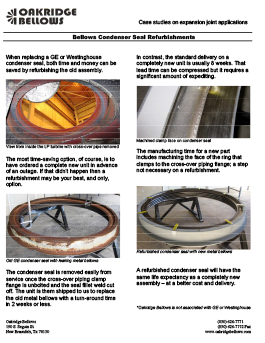

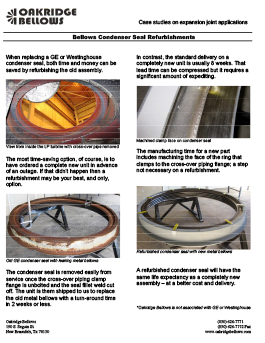

Bellows Condenser Seal Refurbishments

January 13, 2018There is no excerpt because this is a protected post.

Read More

Bellows Condenser Seal Refurbishments

October 27, 2014There is no excerpt because this is a protected post.

Read More

Condenser Seal Replacements

January 13, 2018There is no excerpt because this is a protected post.

Read More

Condenser Seal Replacements

October 27, 2014There is no excerpt because this is a protected post.

Read More

The Ultimate Flue Gas Ducting Expansion Joint

January 13, 2018There is no excerpt because this is a protected post.

Read More

The Ultimate Flue Gas Ducting Expansion Joint

October 27, 2014There is no excerpt because this is a protected post.

Read More

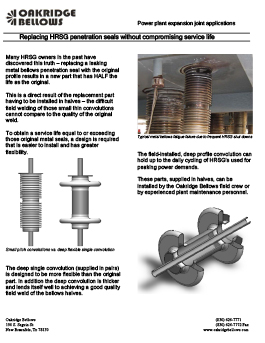

Replacing HRSG penetration seals without compromising service life

January 13, 2018There is no excerpt because this is a protected post.

Read More

Replacing HRSG penetration seals without compromising service life

October 27, 2014There is no excerpt because this is a protected post.

Read More

GE Cross-Over Expansion Joint Repairs

January 13, 2018There is no excerpt because this is a protected post.

Read More

GE Cross-Over Expansion Joint Repairs

October 27, 2014There is no excerpt because this is a protected post.

Read More

Turbine Replacement Bellows

January 13, 2018There is no excerpt because this is a protected post.

Read More

Turbine Replacement Bellows

October 27, 2014There is no excerpt because this is a protected post.

Read More

GE Turbine Cross Over Rebuilds

January 13, 2018There is no excerpt because this is a protected post.

Read More

GE Turbine Cross Over Rebuilds

October 27, 2014There is no excerpt because this is a protected post.

Read More

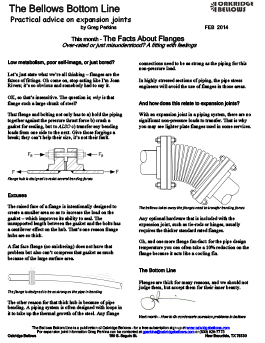

Flanges On Expansion Joints (*NEW)

October 17, 2014Low metabolism, poor self-image, or just bored? Let’s just state what we’re all thinking – flanges are the fatsos of fittings. Oh come on, stop acting like I’m Joan Rivers; it’s so obvious and somebody had to say it. OK, so that’s insensitive. The question is; why is that flange such a large chunk of

Read More

Avoiding Acid Condensate On Bellows

September 26, 2014

Understanding Expansion Joint Pressure Thrust

March 6, 2020

Titanium Bellows

July 10, 2014Pulp & Paper Challenges To 317L The bleaching service in pulp & paper plants has always been tough on expansion joints. Stainless steels such as 316L and 317L have held up as the go-to material for years. Changes in the bleaching concentrations and increased temperatures have created corrosives that have shortened the service lives of

Read More

Cor-Ten – The forgotten steel

July 10, 2014COR-TEN Steel In Flue Gas Ducting Expansion Joints The funny named steel that won’t go away. Ducting, Old School Many older power plant boilers have metal rectangular expansion joints made with steel by the name of CORTEN. This steel gets its name because of its improved corrosion resistance (‘Cor’) and its higher tensile strength (‘Ten’).

Read More

Hinged Expansion Joints in FRP Piping

July 10, 2014Where metal meets plastic Fiberglass Reinforced Plastic (FRP) piping and vessels have a higher thermal growth rate than carbon steel and even stainless steel piping. FRP does have more flexibility, and in smaller diameters, pipe loops are the way to go for taking up those higher deflections. For larger diameter FRP piping, consider using a

Read More

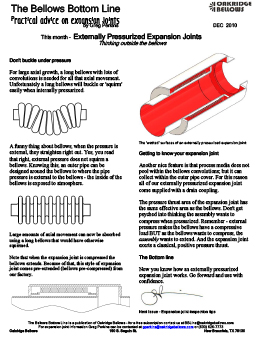

Externally Pressurized Expansion Joints

July 10, 2014Don’t buckle under pressure For large axial growth, a long bellows with lots of convolutions is needed for all that axial movement. Unfortunately a long bellows will buckle or ‘squirm’ easily when internally pressurized. A funny thing about bellows, when the pressure is external, they straighten right out. Yes, you read that right, external pressure

Read More

625 vs 625 LCF Bellows Performance

July 10, 2014625 – What’s in a name? Exactly what is the difference between alloy 625 and alloy 625LCF®? First of all LCF® is a trademark of Special Metals®. Under advice of our legal counsel®, I note a Trademark® to avoid getting our pants® sued off®. Yes, I know, EVERYBODY refers to the ‘enhanced’ alloy 625 for

Read More

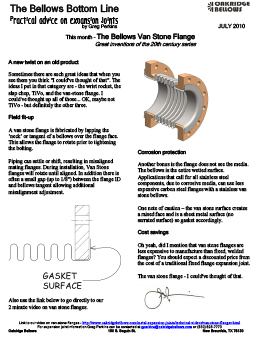

Vanstone Flanges On Bellows Expansion Joints

July 10, 2014A new twist on an old product Sometimes there are such great ideas that when you see them you think “I could’ve thought of that”. The ideas I put in that category are – the wrist rocket, the slap chop, TiVo, and the van-stone flange. I could’ve thought up all of those… OK, maybe not

Read More

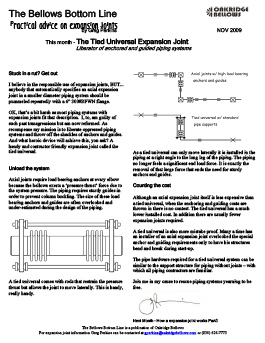

Tied Universal Expansion Joints – Best Bang For The Buck

July 10, 2014Stuck in a rut? Get out I believe in the responsible use of expansion joints, BUT… anybody that automatically specifies an axial expansion joint in a smaller diameter piping system should be pummeled repeatedly with a 6″ 300#RFWN flange. OK, that’s a bit harsh as most piping systems with expansion joints fit that description. I,

Read More

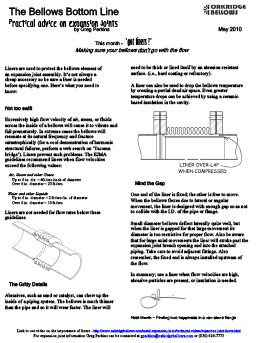

Liners On Metal Expansion Joints

July 10, 2014Liners are used to protect the bellows element of an expansion joint assembly. It’s not always a cheap accessory so be sure a liner is needed before specifying one. Here’s what you need to know: Not too swift Excessively high flow velocity of air, steam, or fluids across the inside of a bellows will cause

Read More

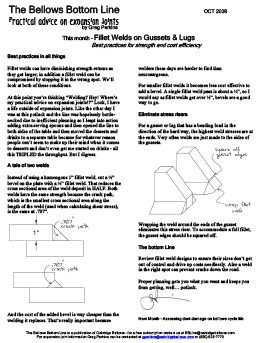

Best Practices On Fillet Welding

July 10, 2014Best practices in all things Fillet welds can have diminishing strength returns as they get larger; in addition a fillet weld can be compromised by stopping it in the wrong spot. We’ll look at both of these conditions. At this point you’re thinking “Welding? Hey! Where’s my practical advice on expansion joints!?” Look, I have

Read More

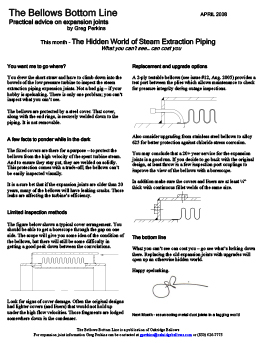

Steam Extraction Expansion Joint Inspection

July 10, 2014You want me to go where? You drew the short straw and have to climb down into the bowels of the low pressure turbine to inspect the steam extraction piping expansion joints. Not a bad gig – if your hobby is spelunking. There is only one problem; you can’t inspect what you can’t see. The

Read More

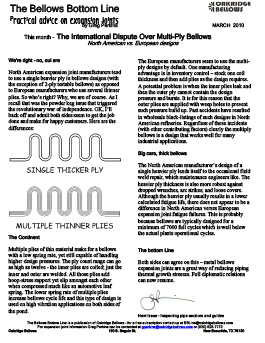

The International Dispute over Multi-Ply Bellows

July 10, 2014We’re right – no, oui are North American expansion joint manufacturers tend to use a single heavier ply in bellows designs (with the exception of 2-ply testable bellows) as opposed to European manufacturers who use several thinner plies. So who’s right? Why, we are of course. As I recall that was the powder keg issue

Read More

Metal vs Fabric Ducting Expansion Joint

July 10, 2014They don’t make ‘em like they used to Your original metal boiler ducting expansion joints were 25+ years old, so you replaced them, or lagged over them with PTFE coated fabric belts. That was 7 years ago, and after numerous patch repairs the entire belt needs to be replaced again. So much for the inexpensive

Read More

Driven to excellence in all things. I am the last man on the planet that still changes his own oil. Many of my friends scoff at this quaint habit and present spreadsheets and graphs comparing the cheap cost of the neighborhood quickie-lube. I am unmoved. I squeeze more life out of my engines by doing

Read More

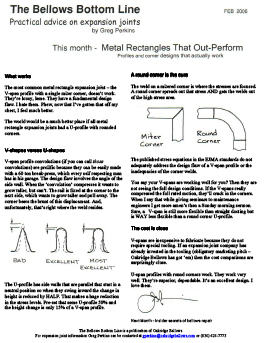

Metal Rectangular Expansion Joints That Last

July 9, 2014What works The most common metal rectangle expansion joint – the V-span profile with a single miter corner, doesn’t work. They’re lousy, lame. They have a fundamental design flaw. I hate them. Phew, now that I’ve gotten that off my chest, I feel much better. The world would be a much better place if all

Read More

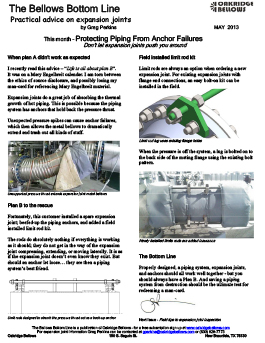

Protecting Piping From Anchor Failures

July 9, 2014Don’t let expansion joints push you around. When plan A didn’t work as expected I recently read this advice – “Life is all about plan B”. It was on a Mary Engelbreit calendar. I am torn between the ethics of source disclosure, and possibly losing my man-card for referencing Mary Engelbreit material. Expansion joints do

Read More

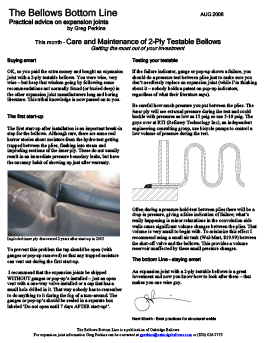

Buying smart OK, so you paid the extra money and bought an expansion joint with a 2-ply testable bellows. You were wise, very wise – but keep that wisdom going by following some recommendations not normally found (or buried deep) in the other expansion joint manufacturers long and boring literature. This tribal knowledge is now

Read More

Refurbishing Old Expansion Joints

July 9, 2014Faithful EJ RexIt’s been a good faithful expansion joint, giving you many years of reliable… and now its time to put it down. Saying goodbye can be hard, but it’s not always necessary. And no, this has nothing to do with http://www.oakridgebellows.com/wp-admin/edit.php?post_type=ttshowcasecloning. That old friend can be refurbished with a new bellows, maybe with even

Read More

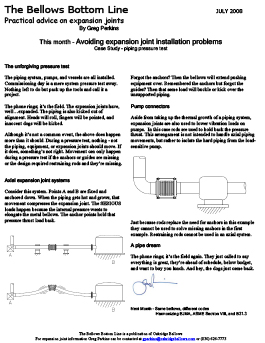

Avoiding Expansion Joint Installation Problems

July 9, 2014The piping system, pumps, and vessels are all installed. Commissioning day is a mere system pressure test away. Nothing left to do but pack up the tools and call it a project. The phone rings; it’s the field. The expansion joints have, well…expanded. The piping is also kicked out of alignment. Heads will roll, fingers

Read More