Avoiding Acid Condensate On Bellows

Cool is over-rated

I realized my kids had become too cool for me when they started jumping out of the car, without saying goodbye, in the school parking lot. In retrospect maybe it was because I was yelling “I LOVE YOU! MAKE GOOD CHOICES!” out the window at the top of my lungs. Payback for all those early years when they threw butter at the tables next to us in restaurants.

Your bellows, on the other hand, can be managed when it gets too cool.

It’s a phase they’re going through

In many flue gas applications temperature can exceed 1000°F; bellows are often internally insulated in order to drop their temperature into ranges where the material has better strength and corrosion-resistant properties. That same insulation can often unintentionally drop the bellows temperature below 250°F, the temperature some gases condense into liquids.

A hot gas mixture of hydrocarbons, sulfur, etc. in a ducting system will stay a gas unless it hits a cool surface. When that happens it condenses on that surface.

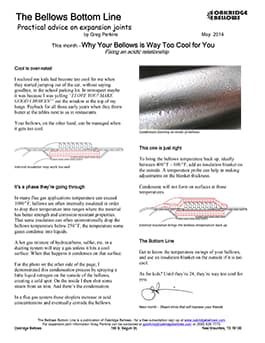

For the photo on the other side of the page, I demonstrated this condensation process by spraying a little liquid nitrogen on the outside of the bellows, creating a cold spot. On the inside I then shot some steam from an iron. And there’s the condensation.

In a flue gas system those droplets increase in acid concentrations and eventually corrode the bellows.

This one is just right

To bring the bellows temperature back up, ideally between 400°F – 600°F, add an insulation blanket on the outside. A temperature probe can help in making adjustments on the blanket thickness.

Condensate will not form on surfaces at those temperatures.

The Bottom Line

Get to know the temperature swings of your bellows, and use an insulation blanket on the outside if it is too cool.

As for kids? Until they’re 24; they’re way too cool for you.

Next month – Steam trivia that will impress your friends.