Titanium Bellows

Pulp & Paper Challenges To 317L The bleaching service in pulp & paper plants has always been tough on expansion joints. Stainless steels such as 316L and 317L have held up as the go-to material for years.

Changes in the bleaching concentrations and increased temperatures have created corrosives that have shortened the service lives of those bellows. Material engineers then sought a better material; they found it in titanium. Titanium? Really? Really. Titanium is a great material for the corrosive environment of the bleaching equipment; significantly extending the service life of the piping expansion joints.

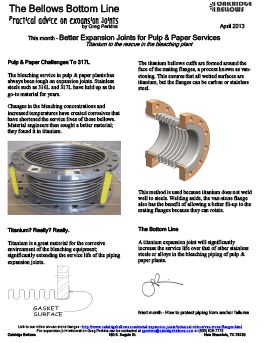

The titanium bellows cuffs are formed around the face of the mating flanges, a process known as vanstoning. This ensures that all wetted surfaces are titanium, but the flanges can be carbon or stainless steel.

This method is used because titanium does not weld well to steels. Welding aside, the van-stone flange also has the benefit of allowing a better fit-up to the mating flanges because they can rotate.

The Bottom Line

A titanium expansion joint will significantly increase the service life over that of other stainless steels or alloys in the bleaching piping of pulp & paper plants.