Hinged Expansion Joints in FRP Piping

Where metal meets plastic

Fiberglass Reinforced Plastic (FRP) piping and vessels have a higher thermal growth rate than carbon steel and even stainless steel piping. FRP does have more flexibility, and in smaller diameters, pipe loops are the way to go for taking up those higher deflections.

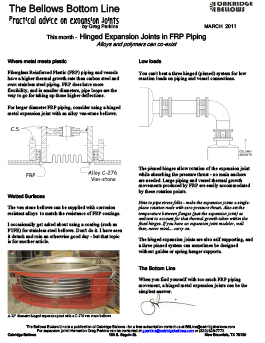

For larger diameter FRP piping, consider using a hinged metal expansion joint with an alloy van-stone bellows.

Wetted Surfaces

The van stone bellows can be supplied with corrosion resistant alloys to match the resistance of FRP coatings.

I occasionally get asked about using a coating (such as PTFE) for stainless steel bellows. Don’t do it. I have seen it detach and ruin an otherwise good day – but that topic is for another article.

A 32″ diameter hinged expansion joint with a C-276 van stone bellows

Low loads

You can’t beat a three hinged (pinned) system for low reaction loads on piping and vessel connections.

The pinned hinges allow rotation of the expansion joint while absorbing the pressure thrust – no main anchors are needed. Large piping and vessel thermal growth movements produced by FRP are easily accommodated by these rotation points.

Note to pipe stress folks – make the expansion joints a single- plane rotation node with zero pressure thrust. Also set the temperature between flanges (just the expansion joint) as ambient to account for that thermal growth taken within the fixed hinges. If you have an expansion joint modeler, well then, never mind… carry on.

The hinged expansion joints are also self supporting, and a three pinned system can sometimes be designed without guides or spring hanger supports.

The Bottom Line

When you find yourself with too much FRP piping movement, a hinged metal expansion joints can be the simplest answer.