Water Hammer In Piping

The big bang

You shut off the sink faucet and immediately hear a bang and then the after-shock rattling in the piping. You, my friend, have just experienced an effect known as water hammer.

Not only is water hammer a common house hold annoyance, it bounces around steam and process piping all too often. Although this does not call for an expansion joint solution, feel free to call and chat as we think of ourselves as piping system therapists sitting around in cardigan sweaters ready to validate you; plus we get community service hours for this.

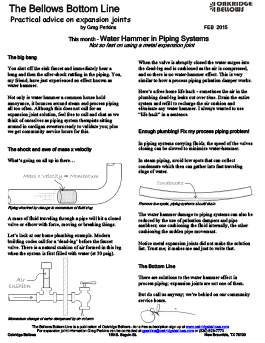

The shock and awe of mass x velocity

What’s going on all up in there…

A mass of fluid traveling through a pipe will hit a closed valve or elbow with force, moving or breaking things.

Let’s look at our home plumbing example. Modern building codes call for a ‘dead-leg’ before the faucet valve. There is a natural cushion of air formed in this leg when the system is first filled with water (at 50 psig).

When the valve is abruptly closed the water surges into the dead-leg and is cushioned as the air is compressed, and so there is no water-hammer effect. This is very similar to how a process piping pulsation damper works.

Here’s a free home life hack – sometimes the air in the plumbing dead-leg leaks out over time. Drain the entire system and refill to recharge the air cushion and eliminate any water hammer. I always wanted to use “life hack” in a sentence.

Enough plumbing! Fix my process piping problem!

In piping systems carrying fluids, the speed of the valves closing can be slowed to minimize water-hammer.

In steam piping, avoid low spots that can collect condensate which then can gather into fast traveling slugs of water.

The water hammer damage to piping systems can also be reduced by the use of pulsation dampers and pipe snubbers; one cushioning the fluid internally, the other cushioning the sudden pipe movement.

Notice metal expansion joints did not make the solution list. Trust me; it makes me sad just to write that.

The Bottom Line

There are solutions to the water hammer effect in process piping; expansion joints are not one of them.

But do call us anyway; we’re behind on our community service hours.