Understanding Bellows Internal Pressure

Understanding Bellows Pressure Capacity

Simple concepts of convoluted shapes

K.I.S.S. – Keep It Simple Moron

Ever read a copy of Scientific American? I pretended to once. Too many words, not enough pictures. I can tell you from personal experience that it does not impress girls when you are holding a publication upside down. Give me simple every time. And pictures; lots of pictures.

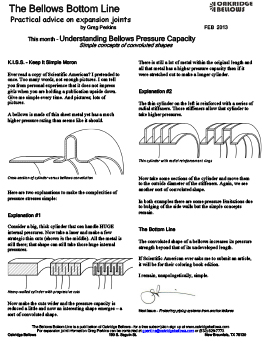

A bellows is made of thin sheet metal yet has a much higher pressure rating than seems like it should. Cross‐section of cylinder versus bellows convolution Here are two explanations to make the complexities of pressure stresses simple:

Explanation #1

Consider a big, thick cylinder that can handle HUGE internal pressures. Now take a laser and make a few strategic thin cuts (shown in the middle). All the metal is still there; that shape can still take those huge internal pressures.

Heavy‐walled cylinder with progressive cuts Now make the cuts wider and the pressure capacity is reduced a little and now an interesting shape emerges – a sort of convoluted shape.

There is still a lot of metal within the original length and all that metal has a higher pressure capacity than if it were stretched out to make a longer cylinder.

Explanation #2

The thin cylinder on the left is reinforced with a series of radial stiffeners. Those stiffeners allow that cylinder to take higher pressures.

Thin cylinder with radial reinforcement rings Now take some sections of the cylinder and move them to the outside diameter of the stiffeners. Again, we see another sort of convoluted shape.

In both examples there are some pressure limitations due to bulging of the side walls but the simple concepts remain.

The Bottom Line

The convoluted shape of a bellows increases its pressure strength beyond that of its undeveloped length. If Scientific American ever asks me to submit an article, it will be for their coloring book edition.

I remain, unapologetically, simple.