Liners On Metal Expansion Joints

Liners are used to protect the bellows element of an expansion joint assembly. It’s not always a cheap accessory so be sure a liner is needed before specifying one. Here’s what you need to know:

Not too swift

Excessively high flow velocity of air, steam, or fluids across the inside of a bellows will cause it to vibrate and fail prematurely. In extreme cases the bellows will resonate at its natural frequency and fracture catastrophically (for a cool demonstration of harmonic structural failures, perform a web search on ‘Tacoma bridge’). Liners prevent such problems. The EJMA guidelines recommend liners when flow velocities exceed the following values:

Air, Steam and other Gases

Up to 6 in. dia. – 4ft./sec./inch of diameter Over 6 in. diameter – 25 ft./sec.

Water and other Liquids

Up to 6 in. diameter – 2 ft./sec./in. of diameter Over 6 in. diameter – 10 ft./sec.

Liners are not needed for flow rates below these guidelines.

The Gritty Details

Abrasives, such as sand or catalyst, can chew up the inside of a piping system. The bellows is much thinner than the pipe and so it will wear faster. The liner will

need to be thick or lined itself by an abrasion resistant surface. (i.e., hard coating or refractory).

A liner can also be used to drop the bellows temperature by creating a partial dead air space. Even greater temperature drops can be achieved by using a ceramic based insulation in the cavity.

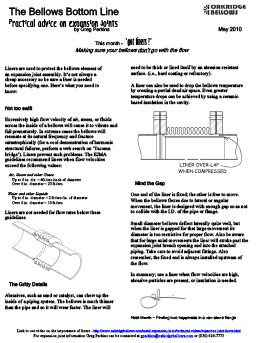

Mind the Gap

One end of the liner is fixed; the other is free to move. When the bellows flexes due to lateral or angular movement, the liner is designed with enough gap so as not to collide with the I.D. of the pipe or flange.

Small diameter bellows deflect laterally quite well, but when the liner is gapped for that large movement its diameter is too restrictive for proper flow. Also be aware that for large axial movements the liner will stroke past the expansion joint breach opening and into the attached piping. Take care to avoid adjacent fittings. Also remember, the fixed end is always installed upstream of the flow.

In summary; use a liner when flow velocities are high, abrasive particles are present, or insulation is needed.