Metal Rectangular Expansion Joints That Last

What works

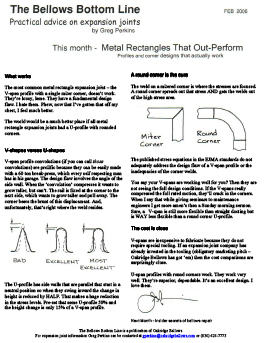

The most common metal rectangle expansion joint – the V-span profile with a single miter corner, doesn’t work. They’re lousy, lame. They have a fundamental design flaw. I hate them. Phew, now that I’ve gotten that off my chest, I feel much better.

The world would be a much better place if all metal rectangle expansion joints had a U-profile with rounded corners.

V-shapes verses U-shapes

span profile convolutions (if you can call those convolutions) are prolific because they can be easily made with a 60 ton break-press, which every self respecting man has in his garage. The design flaw involves the angle of the side wall. When the ‘convolution’ compresses it wants to grow taller, but can’t. The rail is fixed at the corner to the next side, which wants to grow taller and pull away. The corner bears the brunt of this displacement. And, unfortunately, that’s right where the weld resides.

The U-profile has side walls that are parallel that start in a neutral position so when they swing inward the change in height is reduced by HALF. That makes a huge reduction in the stress levels. Pre-set that same U-profile 50% and the height change is only 15% of a V-span profile.

A round corner is the cure

The weld on a mitered corner is where the stresses are focused. A round corner spreads out that stress AND gets the welds out of the high stress area.

The published stress equations in the EJMA standards do not adequately address the design flaw of a V-span profile or the inadequacies of the corner welds.

You say your V-spans are working well for you? Then they are not seeing the full design conditions. If the V-spans really compressed the full rated motion, they’ll crack in the corners. When I say that while giving seminars to maintenance engineers I get more amen’s than a Sunday morning sermon. Sure, a V-span is still more flexible than straight ducting but is WAY less flexible than a round corner U-profile.

The cost is close

V-spans are inexpensive to fabricate because they do not require special tooling. If an expansion joint company has already invested in the tooling (obligatory marketing pitch – Oakridge Bellows has got ‘em) then the cost comparisons are surprisingly close.

U-span profiles with round corners work. They work very well. They’re superior, dependable. It’s an excellent design. I love them.